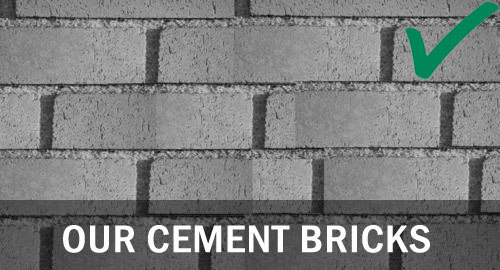

PCC (PLAIN CEMENT CONCRETE) BRICKS

INTRODUCTION

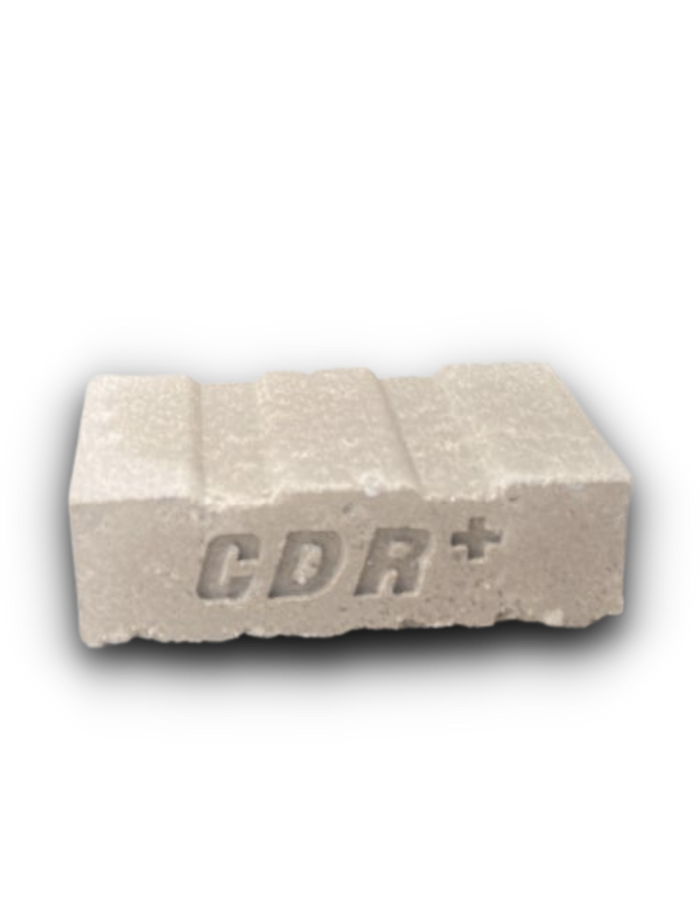

The PCC Brick is a masonry unit composed of OPC/PPC cement, water, sand, aggregate, fly ash (optional up to 20 per cent) and brick additive. This produces a grey brick with frog and with a fine surface texture. It is also known as concrete brick. The crushed stone that goes into the manufacture of cement bricks is often what gives them their strength.

Enquire Now

https://youtu.be/JEspWTu6vp0

USAGE

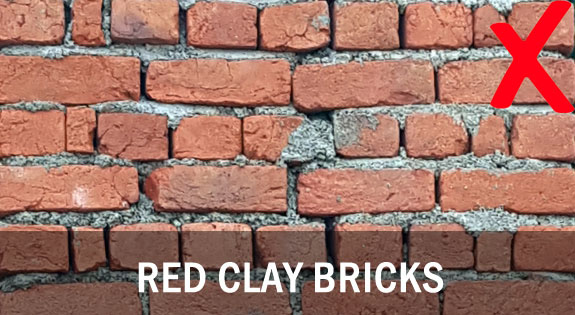

PCC bricks can be used as an alternative material for burnt clay bricks which is one of the important building materials used for construction of housing and buildings.

Enquire Now

Advantages

Why you should prefer our PCC Bricks

Appearance

These bricks, resembling cement, boast uniformity, smooth finish, and no need for plastering. Dense and crack-free, they lack visible defects and are less porous. Admixtures can enhance their strength. Uniform in size (230x110x75mm), they simplify construction compared to variable-sized PCC bricks.

Structural Capability

We offer multiple load-bearing grades, reduce mortar plastering costs, and enhance the aesthetic appeal of brickwork. Their density ensures structural compatibility and earthquake resistance. These bricks have an average compressive strength of 15 N/mm2, surpassing ordinary PCC bricks at 11 N/mm2.

Durability and moisture resistance

After proper pointing of joints, the bricks can be directly painted in dry distemper and cement paints, without the backing coating of plaster. Rectangular faced with sharp corners, solid. Water absorption is lesser than ordinary PCC bricks available in the market, reducing dampness of the walls.

Buildability, availability and cost

Easy workability and high compressive strength, reducing breakage and waste, resulting in a neat finish with thinner joints and plaster. The construction technique remains same as regular bricks ensuring easy change of material, without requiring additional training for the masons.

Get a Quote

TECHNICAL LITERATURE

Details of Raw Material:

1. Cement – OPC/PPC

2. Aggregate

3. Fly ash (optional. Can be used up to 20 per cent)

4. Stone Dust

5. Crusher Sand

5. Chemical admixture

6. Water

Dimensions:

Brick with Frog

Size: 230 mm x 110 mm x 75 mm

Average Compressive Strength: 15 N/mm2

Average Gross Density: 1900 kg/m3

Manufactured by using Block making machine (Vibro Compaction Method)

Conforms to IS Code 2185-1 (2005)